7 Key Benefits of Mold Flow Diecast

Mold flow diecast is a powerful technique in manufacturing, crucial for producing high-quality parts efficiently. It involves simulating the flow of molten material into a mold cavity to predict and optimize the die casting process. This helps manufacturers identify and resolve potential issues before production, resulting in significant advantages. Understanding the benefits of mold flow diecast can greatly improve your design and manufacturing workflow, leading to better products and reduced costs. This guide explores seven key advantages, highlighting the importance of this technology in modern manufacturing and design processes. Investing in mold flow diecast simulation can provide a clear competitive edge in industries that demand precision and efficiency in their production cycles.

Enhanced Design Optimization

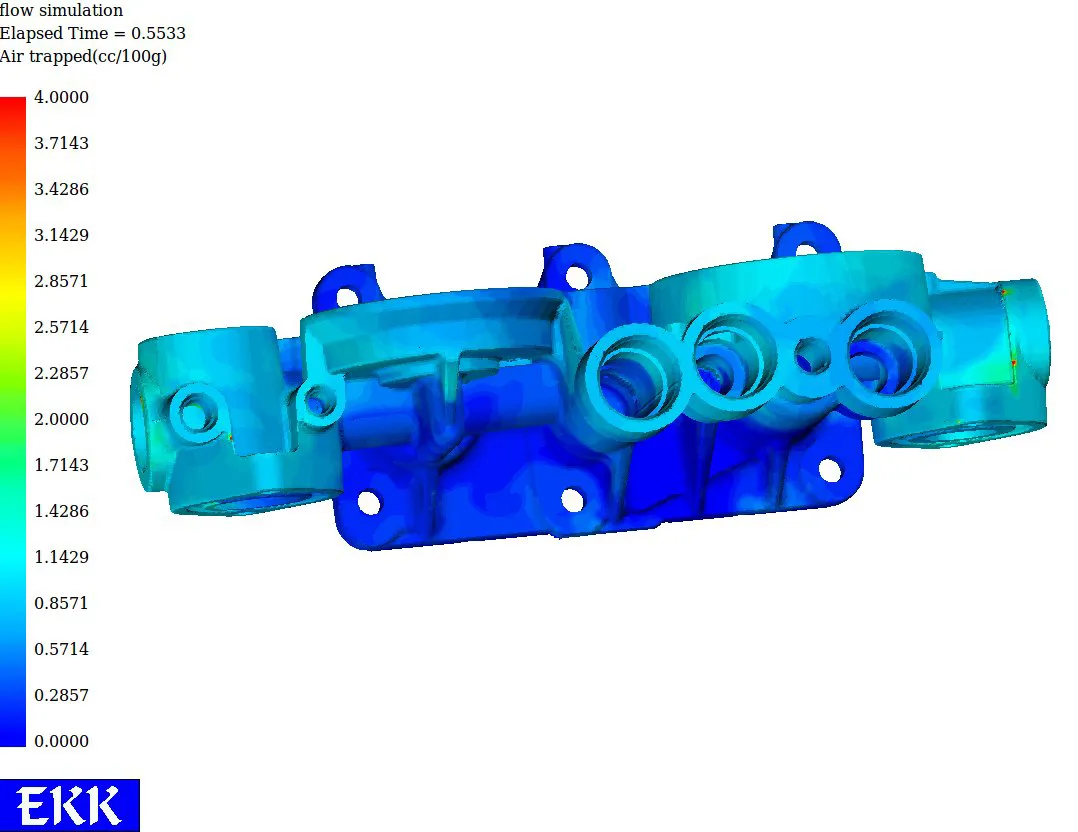

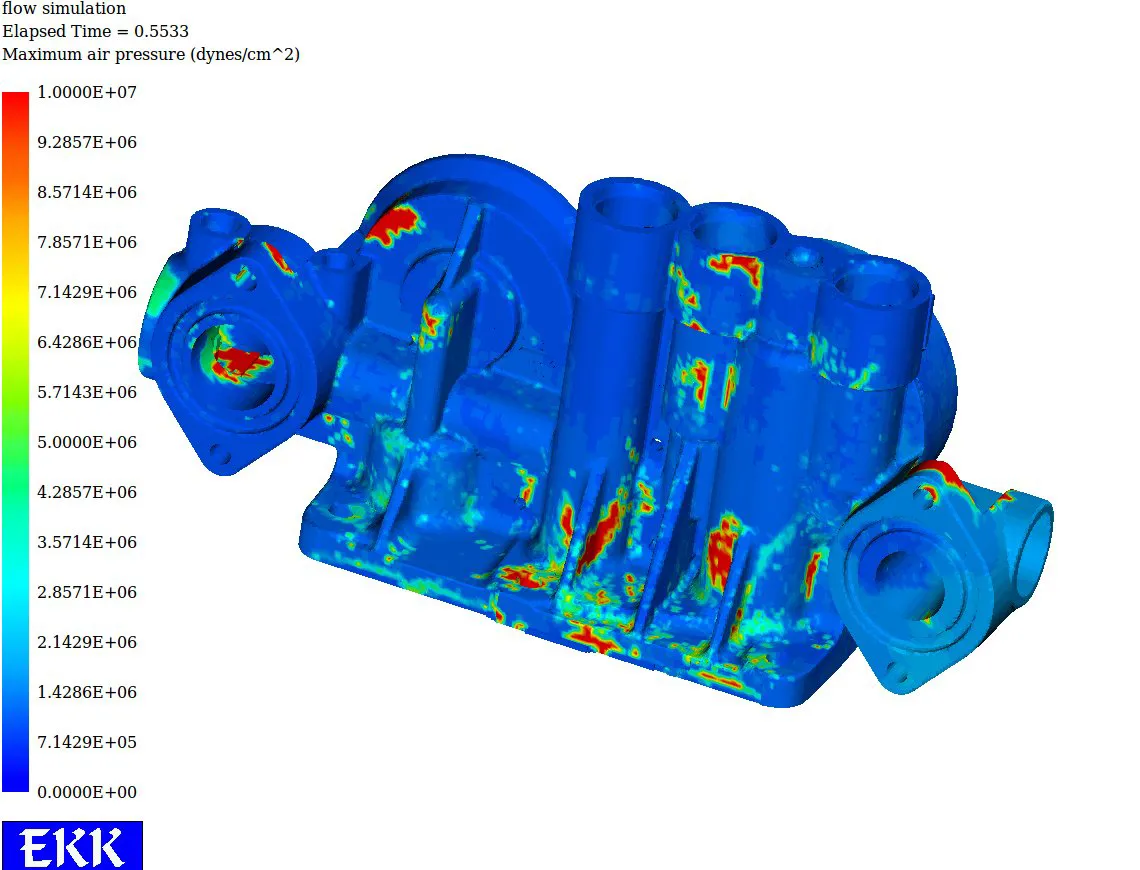

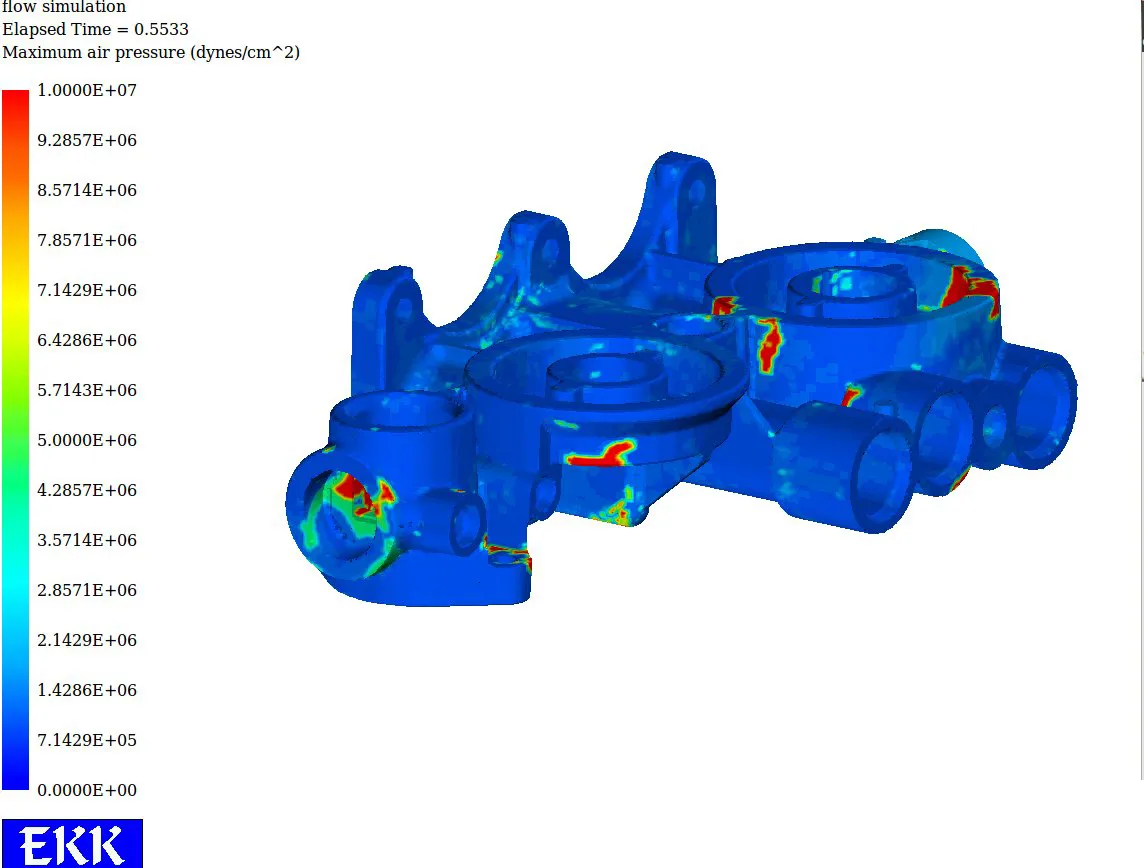

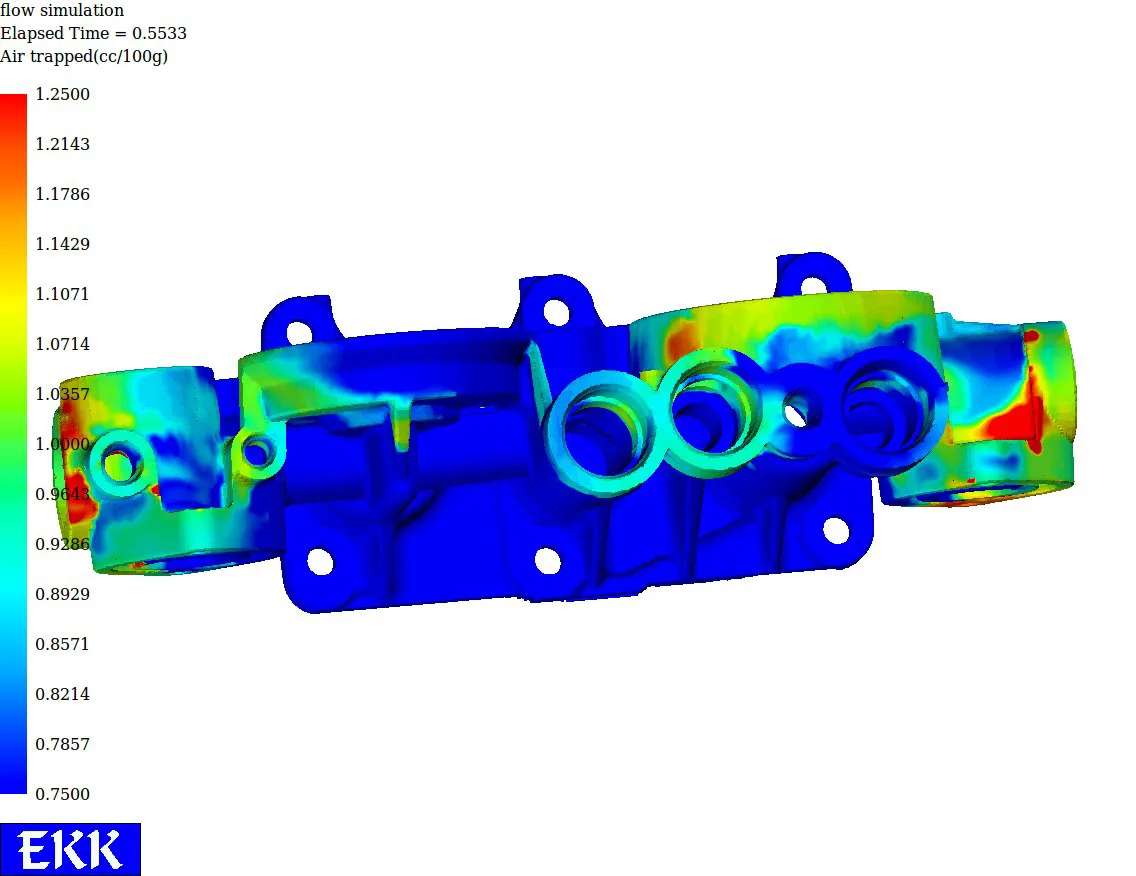

One of the primary benefits of mold flow diecast is its ability to enhance design optimization. Simulation software allows designers to evaluate different design iterations and identify potential issues such as weld lines, air traps, and excessive pressure drops. This early detection allows for design modifications that improve part quality, reduce defects, and optimize the material flow. Designers can adjust gate locations, runner systems, and cooling channels, ensuring the molten material fills the mold uniformly. By using mold flow analysis, designers can create parts that are not only aesthetically pleasing but also structurally sound and manufacturable, resulting in designs that are more robust and efficient in their performance and manufacturing processes. This iterative process significantly reduces the need for costly physical prototypes and revisions.

Faster Prototyping and Reduced Lead Times

Mold flow diecast significantly accelerates the prototyping phase. By simulating the die casting process, engineers can evaluate design changes virtually, eliminating the need to build and test multiple physical prototypes. This reduces the time it takes to bring a product to market, as design flaws are identified and corrected before production begins. The ability to simulate the process also allows for quicker iterations, enabling designers to experiment with different materials, gate locations, and cooling strategies. This results in reduced lead times and faster product development cycles, giving manufacturers a competitive edge in today’s fast-paced market. Quicker prototyping allows for faster feedback and design refinement, enabling products to be launched sooner.

Improved Part Quality and Dimensional Accuracy

Mold flow diecast ensures improved part quality and dimensional accuracy. By simulating the filling, packing, and cooling stages of the die casting process, engineers can optimize the mold design to minimize defects like porosity, warpage, and shrinkage. This results in parts with consistent dimensions and high structural integrity, reducing the need for rework or rejection. The simulation also helps identify the optimal cooling strategies to ensure uniform cooling rates, which are critical for maintaining dimensional stability. This leads to higher-quality products that meet stringent industry standards and customer expectations. Proper flow analysis minimizes potential flaws, producing parts that work as intended, time and again.

Cost-Effectiveness for High-Volume Production

Die casting, optimized through mold flow analysis, is exceptionally cost-effective for high-volume production. The upfront investment in simulation software and mold design is offset by significant savings in the long run. The reduction in defects, waste, and rework translates to lower production costs per part. The ability to optimize the process also leads to more efficient use of materials and energy, further reducing operational expenses. Moreover, faster production cycles mean quicker returns on investment. This makes mold flow diecast particularly advantageous for industries that require mass production, like automotive, electronics, and consumer goods. This will significantly increase profitability and competitiveness.

Material Selection Flexibility

Mold flow diecast offers considerable flexibility in material selection. Simulation tools allow engineers to evaluate the performance of various materials, such as aluminum, zinc, and magnesium alloys, under different casting conditions. This enables them to choose the material that best suits the product’s functional requirements and cost considerations. Simulation can predict how different materials will flow, solidify, and react within the mold, allowing for informed decisions. This flexibility is crucial, as the right material choice affects product performance, durability, and cost-effectiveness. Advanced simulations can also take into account material properties, allowing for more accurate predictions. Choosing the optimal material is critical for both the success and the longevity of a product.

Increased Design Freedom and Complexity

With mold flow diecast, designers enjoy greater freedom and can create complex geometries that would be challenging or impossible with traditional manufacturing methods. The simulation capabilities allow for the precise control of material flow, enabling the production of intricate parts with thin walls, complex features, and tight tolerances. This opens doors to innovative designs and functional improvements. The technology helps prevent issues before production, making it easier to realize ambitious designs. The ability to manufacture parts with complex features can result in better product performance and aesthetics, and with mold flow, designers can explore more intricate designs while maintaining the integrity of the manufacturing process.

Reduced Risk of Manufacturing Defects

Mold flow diecast significantly reduces the risk of manufacturing defects. By simulating the die casting process, potential issues such as air entrapment, weld lines, and non-uniform cooling can be identified and addressed. This leads to a decrease in scrap rates, rework, and material waste. The simulation allows for the optimization of various parameters, like gate locations, runner systems, and cooling channel designs, ensuring the molten material fills the mold properly, thus reducing the likelihood of defects. Reduced defects not only save time and money but also enhance product quality, customer satisfaction, and overall brand reputation. Early intervention, achieved through detailed analysis, prevents defects from occurring, leading to streamlined production cycles.

Better Understanding and Prediction of Flow Behavior

Mold flow analysis provides a deeper understanding of how the molten material flows within the mold, which is essential for optimizing the die casting process. The simulation software predicts how the material fills the mold, how it solidifies, and how it cools. This understanding enables engineers to fine-tune process parameters, such as injection speed, temperature, and pressure, to achieve optimal results. The detailed flow analysis helps to identify potential problems before they arise, allowing for preventive measures to be taken. This results in better-quality parts, reduced waste, and more efficient production runs. With predictive insights, engineers can anticipate and resolve issues, maximizing productivity.

Conclusion

Mold flow diecast offers numerous benefits, including design optimization, faster prototyping, and improved part quality. It is a critical technology for anyone involved in die casting. The ability to predict and optimize the die casting process leads to greater efficiency, reduced costs, and the production of high-quality parts. Embracing this technology allows manufacturers to stay ahead of the competition, improve product quality, and meet the demands of a rapidly evolving marketplace. By understanding and utilizing the advantages of mold flow diecast, businesses can gain a significant edge in design, production, and market performance. Investing in mold flow analysis is an investment in the future of your manufacturing process, yielding long-term benefits.