What Makes the Best Glue for Diecast Models

Choosing the best glue for diecast models is crucial for successful repairs, restorations, and even simple assembly tasks. The right adhesive can mean the difference between a durable, seamless finish and a frustrating outcome. Diecast models, typically made from zinc alloy and often featuring plastic and other materials, require a glue that provides a strong bond without damaging the delicate components. This guide explores the key factors to consider, various glue types, and provides recommendations for the top choices available, ensuring your diecast models remain in pristine condition or are beautifully restored.

Factors to Consider

Several factors influence the selection of the best glue for diecast models. Strength is paramount; the adhesive must create a robust bond capable of withstanding handling and minor impacts. Compatibility with the model materials is also critical. Some glues can react with certain plastics or metals, causing damage or weakening the model. Precision application is another key consideration, especially for intricate details. The glue should be easy to apply with accuracy, avoiding messy spills or unwanted adhesive residue. Drying and curing time is an important factor. Some glues dry quickly, making them suitable for fast repairs, while others require more time to fully cure, providing increased strength and flexibility. Finally, the glue’s finish should be transparent or easily concealed, maintaining the model’s aesthetic appeal.

Types of Glue for Diecast Models

Different types of glue cater to the specific needs of diecast models, each with its unique properties and applications. Understanding these options is crucial for selecting the right adhesive for your project. We’ll delve into the most common types, examining their strengths, weaknesses, and ideal uses to help you make an informed decision. From quick-drying super glues to slow-curing epoxies and specialized plastic cements, the world of adhesives offers a solution for every diecast modeling challenge.

Super Glue/Cyanoacrylate

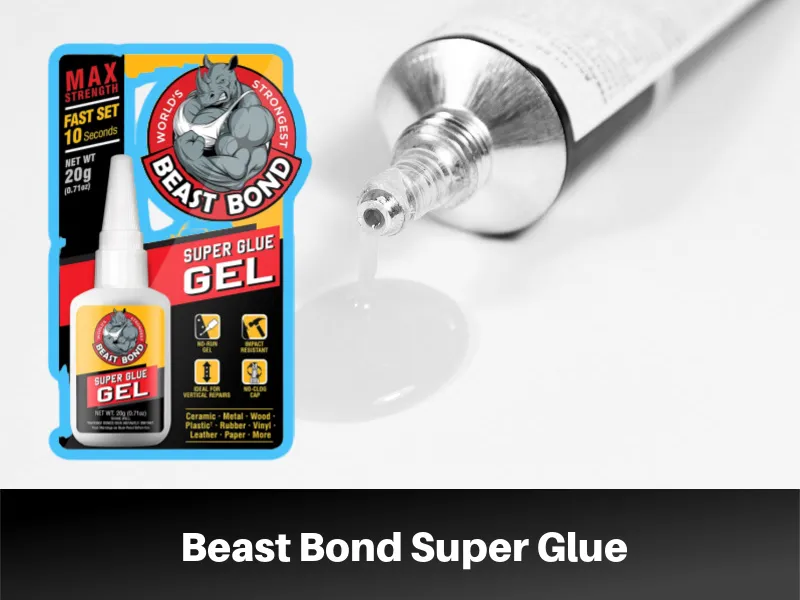

Super glue, also known as cyanoacrylate, is a popular choice for diecast model repairs due to its fast-acting properties and strong bonding capabilities. It forms a quick, durable bond on various surfaces, including metal, plastic, and rubber components commonly found in diecast models. The rapid curing time makes super glue ideal for tasks that require immediate results. However, it’s essential to use super glue with caution. The quick setting can make it challenging to reposition parts, and it can sometimes leave a brittle bond if applied excessively. Additionally, certain formulations can react with some plastics, so always test on a small, inconspicuous area first. Using a gel-based super glue can mitigate some of these issues, offering better control and less risk of running.

Epoxy Resin

Epoxy resin provides an exceptionally strong and durable bond, making it an excellent choice for structural repairs on diecast models. Unlike super glue, epoxy typically comes in two parts that are mixed together, initiating a chemical reaction that results in a hard, permanent bond. This type of glue is well-suited for securing larger parts, filling gaps, and reinforcing weak areas. Epoxy resins offer excellent resistance to temperature fluctuations and chemicals. The slow curing time allows for precise positioning and adjustments before the bond hardens, and it often provides a more flexible, less brittle bond than super glue. It is an excellent choice where long-term durability is crucial. However, mixing and application can be more complex than with other glue types.

Plastic Cement

Plastic cement, specially designed for plastic parts, is an excellent choice for assembling or repairing plastic components often found on diecast models. It works by dissolving the plastic surfaces slightly, creating a fusion bond rather than an adhesive bond. This results in a remarkably strong, permanent connection that’s resistant to impact and stress. Plastic cement is particularly effective for joining plastic-to-plastic components, offering a seamless finish and a bond that often becomes stronger than the plastic itself. However, it is not ideal for bonding metal to plastic, and it’s important to use it in a well-ventilated area because the fumes can be strong. Always test the cement on a small, hidden area to ensure compatibility with the plastic material.

Other Options

Besides the primary options, other adhesives might be useful for specific applications. PVA glue, often used in general crafting, can be suitable for attaching paper or fabric components in a diecast model. Contact cement is another option for bonding large surfaces. Specialized glues designed for specific materials, such as rubber or specific types of plastic, are also available. Consider the material of the parts and the type of bond you need when selecting these options. Always consider the glue’s intended purpose and the materials involved to ensure you get the best results, leading to a well-maintained and enhanced diecast model.

Top 5 Glue Picks for Diecast Models

Choosing the best glue can feel overwhelming, given the many choices available. Here is a list of the top picks, taking into consideration strength, ease of use, and suitability for various diecast model applications. These glues are selected to provide a blend of performance and value, ensuring your model repairs and assembly tasks are efficient and effective.

Glue Pick 1

High-Performance Cyanoacrylate (Super Glue) with a gel consistency is recommended for its strength, precision, and fast-drying properties. This glue excels in bonding metal, plastic, and rubber parts, making it ideal for small repairs and intricate details. Its gel formula prevents running and provides greater control during application. The fast setting time also reduces waiting, perfect for quick fixes.

Glue Pick 2

Two-Part Epoxy is recommended for more robust repairs or structural bonds. This glue offers exceptional strength and resistance to environmental factors. It is best suited for securing larger components, filling gaps, and ensuring the overall durability of your model. Its extended curing time provides flexibility for precise adjustments before the bond solidifies.

Glue Pick 3

Plastic Cement is the best choice for plastic components, especially for plastic-to-plastic connections on the model. It chemically fuses the plastic parts, creating a strong, long-lasting bond. It’s excellent for detailed assemblies and achieving a seamless finish where plastic parts are involved.

Glue Pick 4

Specialty Glue for specific materials. For instance, a rubber-specific adhesive for tires or a clear-drying craft glue to attach delicate paper components.

Glue Pick 5

UV-Curing Glue is a great choice for projects requiring precision. This glue will only cure when exposed to UV light. It is easy to apply and provides a strong bond. It is great for filling tiny gaps.

How to Apply Glue to Diecast Models

Successful diecast model repair and assembly heavily depend on proper glue application techniques. These include essential steps that ensure the glue bonds effectively and maintains the aesthetic integrity of the model. From meticulous surface preparation to applying the adhesive with precision and allowing ample curing time, following these guidelines will optimize your model building and repair efforts.

Surface Preparation

Before applying any glue, proper surface preparation is crucial. Clean the areas to be bonded using isopropyl alcohol or a mild degreaser to remove dust, oils, and any residue. Lightly roughening the surfaces with fine-grit sandpaper can improve adhesion, especially with metal or smooth plastic parts. Ensure surfaces are dry before applying the glue. Accurate preparation guarantees the glue can effectively bond to the surfaces, leading to a stronger and more reliable connection. Neglecting these steps can compromise the bond strength and lead to failure.

Application Techniques

The application technique depends on the glue type. For super glue, apply a small amount to one surface, then quickly press the parts together. With epoxy, mix the two components thoroughly according to the manufacturer’s instructions, then apply a thin, even layer to both surfaces. For plastic cement, apply the cement to the plastic parts and then immediately join the parts. Use precision applicators like needles or fine-tipped nozzles to control the amount of glue and avoid excess spillage. Remove any excess glue with a clean cloth or cotton swab before it dries.

Curing and Drying Time

Allow sufficient time for the glue to cure fully. The curing time varies depending on the glue type and environmental conditions. Super glue typically cures quickly, but it can take up to 24 hours for full strength. Epoxy requires longer curing times, often several hours to overnight, depending on the specific product. Plastic cement bonds almost immediately. Avoid handling or putting stress on the glued parts during the curing process. Check the manufacturer’s instructions for specific drying times and conditions, and always allow extra time to ensure a strong and reliable bond. Proper curing time is critical for achieving maximum strength and durability.

Tips for Successful Diecast Glue Application

Several tips and tricks can help you achieve successful diecast model glue applications. Always test the glue on a scrap piece of material or an inconspicuous area of the model to ensure compatibility. Work in a well-ventilated area, especially when using strong-smelling adhesives. Use the right tools, such as precision applicators, toothpicks, or needles, to apply the glue accurately. Take your time, be patient, and avoid rushing the process. Protect your workspace with a suitable surface to prevent accidental spills. Store glues correctly, according to the manufacturer’s instructions, to maintain their effectiveness. With the right approach, your diecast model projects will be more successful.

By carefully considering the factors that impact the ideal glue choice and following the application guidelines, you’ll be well-equipped to maintain and restore your diecast model collection. Enjoy the process of bringing these miniature masterpieces back to life!