What is Anodising Diecast Aluminum

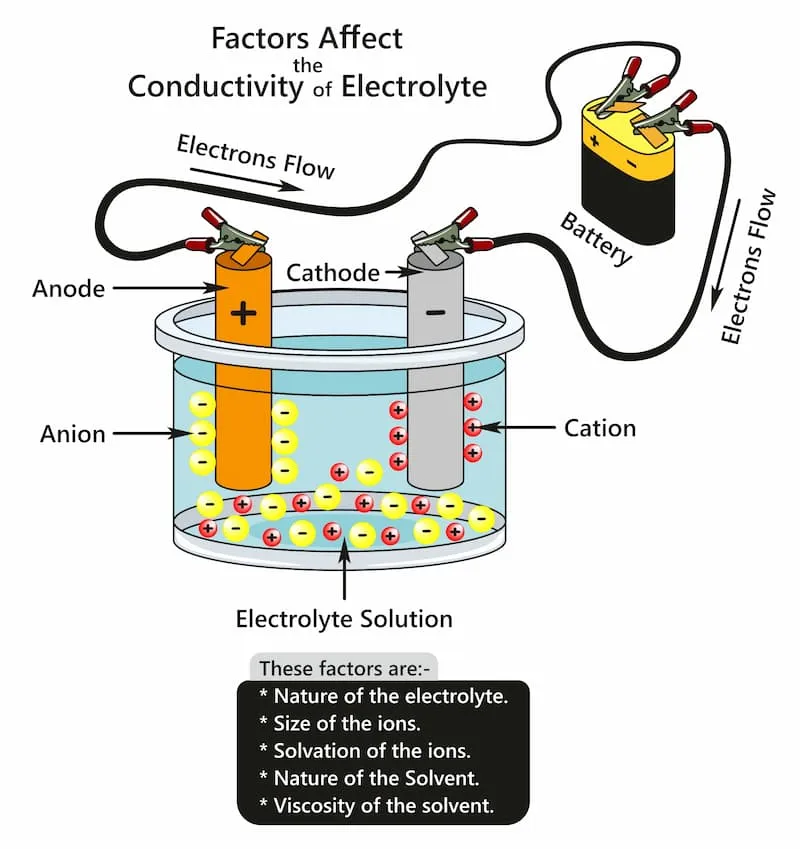

Anodising is an electrochemical process that converts the surface of aluminum into a durable, corrosion-resistant, anodic oxide finish. This process is particularly beneficial for diecast aluminum, a popular choice for manufacturing various products due to its versatility and cost-effectiveness. Diecast aluminum parts often require a protective coating to enhance their performance and lifespan. Anodising provides this protection, offering superior benefits compared to other surface treatments. The process involves immersing the aluminum component in an electrolyte bath and passing an electric current through it. This creates a controlled oxidation of the aluminum surface, resulting in a thicker, more robust oxide layer. This layer isn’t just a coating; it’s an integral part of the metal itself.

The Anodising Process Explained

The anodising process begins with thorough surface preparation, including cleaning and degreasing the diecast aluminum. This step is crucial to ensure the proper adhesion and uniformity of the anodic layer. Once the surface is clean, the component is immersed in an electrolyte solution, typically sulfuric acid, and connected to an electrical circuit. An electric current is then passed through the solution, causing oxygen ions to be released and combine with the aluminum atoms on the surface of the part. This reaction forms an aluminum oxide layer. The thickness of this layer is controlled by factors like the current density, the temperature of the solution, and the duration of the process. Following anodising, the part may undergo sealing, which further enhances its corrosion resistance and durability.

Step-by-Step Guide to Anodising

- Surface Preparation Ensure the aluminum surface is meticulously cleaned to remove any contaminants. This includes degreasing, rinsing, and sometimes etching to create the ideal surface for anodising.

- Anodising Process The aluminum part is submerged in an electrolyte bath, and an electric current is applied. This causes the surface to oxidize, creating the anodic layer.

- Rinsing Thorough rinsing is essential to eliminate any residual chemicals from the anodising process.

- Sealing The final step often involves sealing the porous anodic layer. This process can involve immersion in a boiling water or a nickel acetate solution, enhancing the protective properties of the anodised surface.

Benefits of Anodising Diecast Aluminum

Anodising diecast aluminum offers numerous advantages, making it a preferred choice for various applications. The process not only improves the material’s performance but also enhances its aesthetic appeal. The resulting anodic layer is highly durable and offers superior protection against environmental factors. Let’s explore the key benefits.

Enhanced Corrosion Resistance

One of the primary benefits of anodising diecast aluminum is its exceptional corrosion resistance. The anodic layer acts as a barrier, protecting the underlying aluminum from corrosive elements like moisture, chemicals, and salt. This resistance is particularly crucial in applications where the component is exposed to harsh environments. Anodising extends the lifespan of the aluminum parts, reducing the need for replacements and lowering maintenance costs. The thicker the anodised layer, the greater the protection.

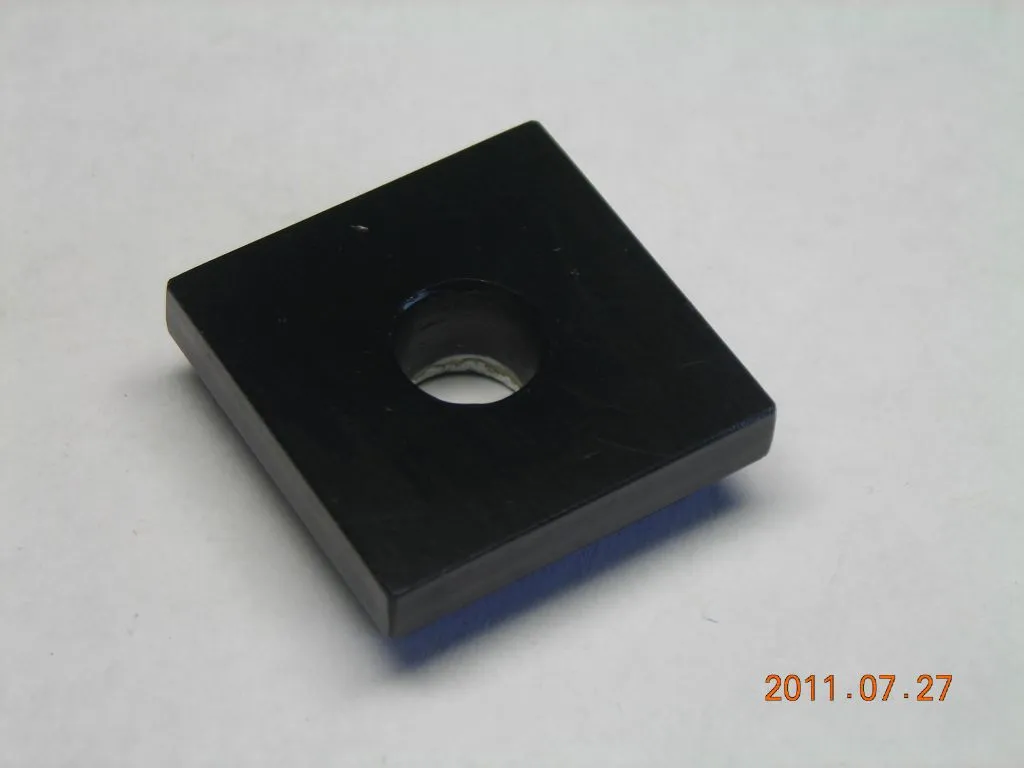

Improved Wear Resistance

Anodising significantly improves the wear resistance of diecast aluminum. The anodic layer is much harder than the base metal, making it more resistant to scratches, abrasion, and general wear and tear. This enhanced durability is especially beneficial for components that experience frequent contact or handling. The increased wear resistance ensures that the parts maintain their functionality and appearance over a longer period.

Aesthetic Appeal and Color Options

Anodising offers a wide range of aesthetic possibilities, allowing for various colors and finishes. The porous nature of the anodic layer enables the absorption of dyes, providing a vibrant and durable color finish. This is particularly useful for products where aesthetics are important, such as consumer electronics, architectural elements, and automotive trim. The ability to customize the color adds value and enhances the overall visual appeal of the finished product.

Increased Durability

The anodic layer created by anodising increases the overall durability of diecast aluminum components. This protective layer is significantly more robust than the base metal. The increased durability contributes to the longevity of the parts, making them suitable for demanding applications. This also helps to withstand harsh environmental conditions, ensuring that products retain their functionality and appearance over time.

Eco-Friendly Process

Anodising is an environmentally friendly process. It does not involve the use of heavy metals or harmful solvents that are often associated with other finishing methods. The process produces minimal waste, and the byproducts can often be recycled. Furthermore, the enhanced durability of anodised parts reduces the need for replacements, ultimately minimizing environmental impact.

Cost-Effectiveness

While the initial cost of anodising may be slightly higher than some other surface treatments, the long-term benefits often make it a more cost-effective solution. The increased durability and corrosion resistance of anodised parts extend their lifespan, reducing the need for frequent replacements and maintenance. The enhanced performance and appearance of anodised components can also add value to the final product, making it more attractive to consumers.

Versatility and Applications

Anodising diecast aluminum is incredibly versatile and can be applied to a wide range of products. The process is suitable for various industries, including automotive, electronics, aerospace, and architecture. It can be used on components of different sizes and shapes, making it a flexible solution for different manufacturing needs. The combination of protection, aesthetics, and durability makes anodising a preferred choice for many applications.

Applications of Anodised Diecast Aluminum

Anodised diecast aluminum finds extensive use across various industries due to its superior properties. The applications highlight the versatility and benefits of this surface treatment. Here are some of the prominent industries where it is widely used.

Automotive Industry

In the automotive industry, anodising is used for a variety of components, including trim, grilles, and interior accents. The process enhances the appearance of these parts while providing protection against corrosion and wear. The ability to add color also allows for the customization of vehicle designs, contributing to brand identity and aesthetic appeal. Anodised parts maintain their finish even with constant exposure to the elements.

Electronics Industry

The electronics industry utilizes anodising for various components, such as computer cases, heat sinks, and electronic enclosures. The anodised layer provides electrical insulation, heat dissipation, and protection against corrosion. The aesthetic options, like colored finishes, make it possible to create visually appealing and functional electronic devices. Anodising contributes to the longevity and reliability of electronic products.

Aerospace Industry

Anodising plays a critical role in the aerospace industry, where components must withstand extreme conditions. It is used on various parts of aircraft and spacecraft for its high strength-to-weight ratio, resistance to corrosion, and durability. The anodised layer protects the aluminum from environmental factors while also improving its bonding properties. This ensures safety and the reliability of aerospace equipment in the most demanding situations.

Tips for Successful Anodising

To achieve the best results when anodising diecast aluminum, several key factors must be considered. Proper surface preparation, the selection of the right anodising solution, and quality control are essential. By following these tips, you can ensure the optimal performance and appearance of your anodised parts.

Surface Preparation

Thorough surface preparation is critical to the success of the anodising process. This includes meticulous cleaning to remove contaminants like oil, grease, and dirt. The surface may also need to be etched to create the optimal surface finish. The final cleaning stage ensures that the anodising layer adheres properly and uniformly, providing maximum protection and aesthetic appeal. Proper surface prep is key to achieving a high-quality finish.

Choosing the Right Anodising Solution

The choice of the anodising solution is essential for achieving the desired properties in the finished product. Sulfuric acid is the most common electrolyte used, but other solutions, like chromic acid, may be used for specific applications. The choice depends on the requirements of the parts being anodised and the desired finish. Ensure you select the appropriate solution to achieve optimal results, considering factors like corrosion resistance, color, and durability.

Maintaining Quality Control

Implementing a robust quality control process is necessary to ensure consistent results. This includes regularly monitoring the electrolyte solution’s concentration and temperature, as well as inspecting the anodised parts for any defects. By maintaining stringent quality control measures, manufacturers can ensure that their anodised components meet the highest standards of performance and appearance. Checking the thickness and the color consistency are important parts of the quality check.

Conclusion

Anodising diecast aluminum is a valuable surface treatment that provides numerous benefits, including enhanced corrosion resistance, improved wear resistance, and aesthetic appeal. It is a versatile and eco-friendly process suitable for various industries, from automotive and electronics to aerospace. By understanding the anodising process, its applications, and following best practices, manufacturers can leverage the full potential of this technology. Anodising not only protects diecast aluminum but also enhances its performance, durability, and visual appeal, making it an excellent choice for a wide range of products.